Glass coloring is the technique which involves adding different substances to glass when it is still in a molten state during manufacture. There are various ways in which color can be added to glass.

The art of coloring glass is an ancient one, and was used extensively in the Egyptian and Roman times. It was almost by accident that early chemists discovered that adding certain ingredients would impart a color to the finished product. Colored glass, specifically, stained glass has been used in churches and other places of worship for centuries. The Arab alchemist Geber was one of the first scientists to discover that adding metallic compounds to glass during the manufacturing process resulted in colored glass. This is still one of the most widely used glass coloring processes today. Glass coloring should not be confused with glass painting. Painting involves creating designs using specific paints and materials on finished glass objects.

Adding Metallic Compounds

The addition of oxides, sulfides, salts, and other compounds of different metals to molten glass at the time of manufacture adds color to glass. The introduction of electrically charged ions which are evenly distributed in the glass during manufacture also gives glass a characteristic color. The table below shows the various compounds that are usually added and the resulting color that is obtained.

| Metal/Compound | Color |

| Cobalt oxide | Deep blue |

| Copper oxide | Turquoise |

| Chromium | Dark green to black |

| Chromium, tin oxide and arsenic | Emerald green |

| Cadmium sulfide | Deep yellow |

| Titanium | Yellowish brown |

| Ferrous oxide | Bluish green |

| High concentration of manganese | Amethyst |

| Nickel with lead crystals | Purple |

| Pure copper | Dark red |

| Gold | Ruby red/cranberry red |

| Silver halides | Yellowish orange to red |

| Didymium | Green or lilac red |

| Tin oxide and antimony | Milky white |

| Cerric Oxide | Brown |

| Magnesium Oxide | Violet |

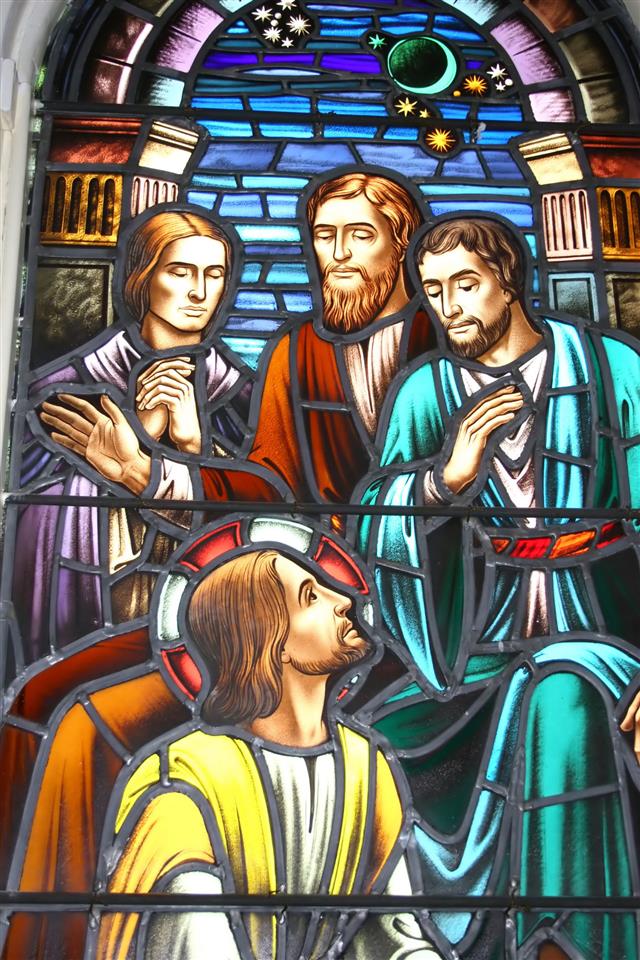

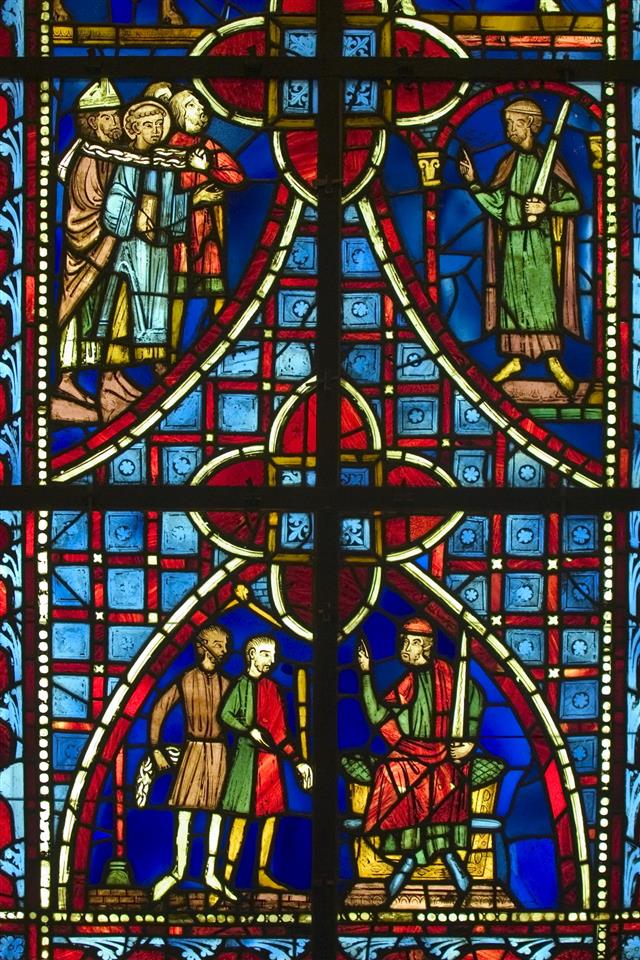

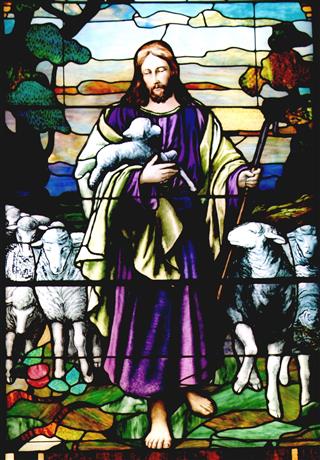

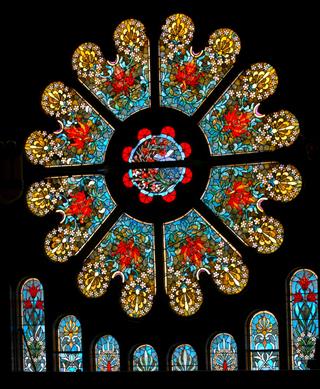

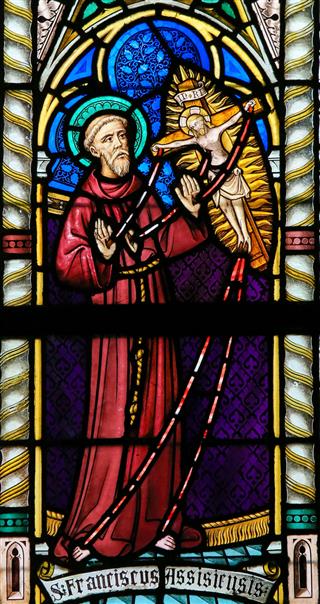

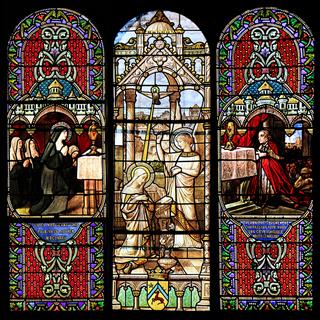

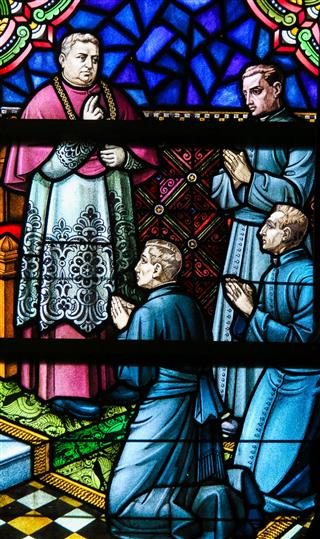

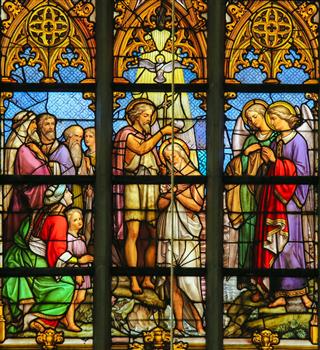

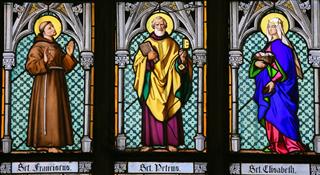

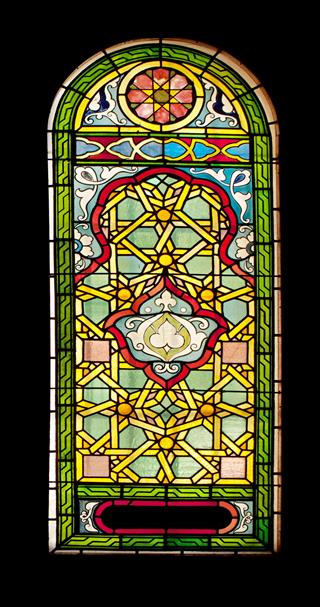

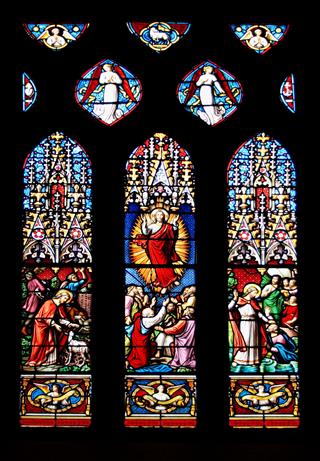

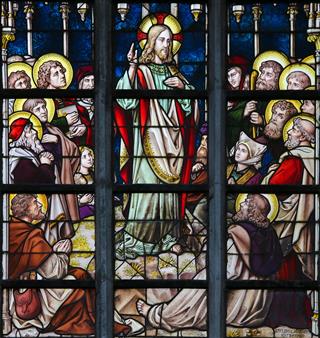

Stained Glass

Finished glass products are brushed with metal oxides to impart the desired color in this process. Then the glass product undergoes further heating which secures the oxide layer to its surface. Upon cooling, this layer can be etched and carved to make designs and patterns. In a different method, stained glass is made by adding metal compounds to obtain the colors and then the glass is rolled into sheets and then cut into desired shapes using special glass cutting tools.

Overlay

In this technique, a ball of glass is blown at one end of a pipe, and moments before it sets, it is introduced into a pot that contains molten glass of the desired color. Depending on the intensity and number of colors required, layers of different colors can be created on the end product. A very creative technique, these layers can be carved and chipped to form intricate designs and patterns and to reveal the different colors underneath.

A slightly different version of overlay is enamel overlay. A glass product is coated with a very thin layer of porcelain enamel, which is usually made of powdered glass combined with metal oxides. The layer can also be cut to create various designs and to show the glass layer underneath.

Another type of overlay is termed as flashing. In this, a glass object is coated with a layer of colored, molten glass for colored effect, which can be engraved to make designs and reveal the original glass layer underneath.

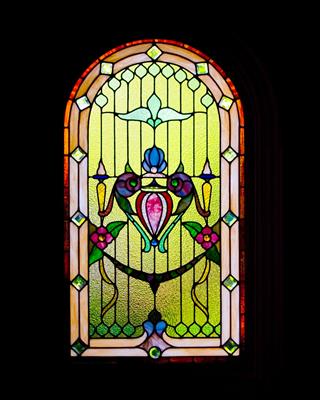

Luster

This process does not color the glass wholly, but renders a hint of a rainbow-like colorful appearance to it. To achieve this effect, metal oxides are layered onto the glass items. Or at the time of manufacture, when the glass is still in a molten state, metal oxide is placed inside the chamber which vaporizes, lightly coloring the glass.

Cased Glass

Two layers of glass are joined together to form cased glass, and both or any one layer can be colored. The outer layer is made first, and during manufacture, one end is cut off, forming a hollow at that end. This part is again positioned into a metal container and molten glass of the desired color is blown into it. Next, these pieces are removed from the container and undergo further heating so they fuse together to form one single piece. Though this technique is similar to flashed glass, the distinguishable characteristic is that the outer layer is thicker than the inner layer in cased glass, whereas flashed glass has a very thin outer coating.

Dichroic Glass

To manufacture dichroic glass, several extremely fine layers of metal oxides and sulfides, not more than a few nanometers in thickness, are vaporized. These vapors are then condensed onto the glass surface. The glass is then coated with a layer of quartz. With multiple layers fused to the glass, the glass exhibits a distinct property of reflecting an entirely different color from the one that is transmitted, and this results in a multitude of colors being produced, depending upon the angle the glass object is viewed from.

Colored glass is used to make a variety of objects like paperweights, marbles, urns, vases, sconces, bottles, beer steins, bowls, etc. Dichroic glass is used to make automobile windshields. Stained glass is popular in churches and mosques and also used in paintings. Colored glass windows are used to control light entering the room, effectively blocking the sun’s radiation and keeping the insides cooler. So if you want to add an element of beauty to your room, as well as maintain privacy and reduce heat, then use colored or stained glass.